There are more than 40,000 incidents in U.S. warehouses every year – many of which can be prevented. Find out how.

Our Story

Setting the Standard in Safety.

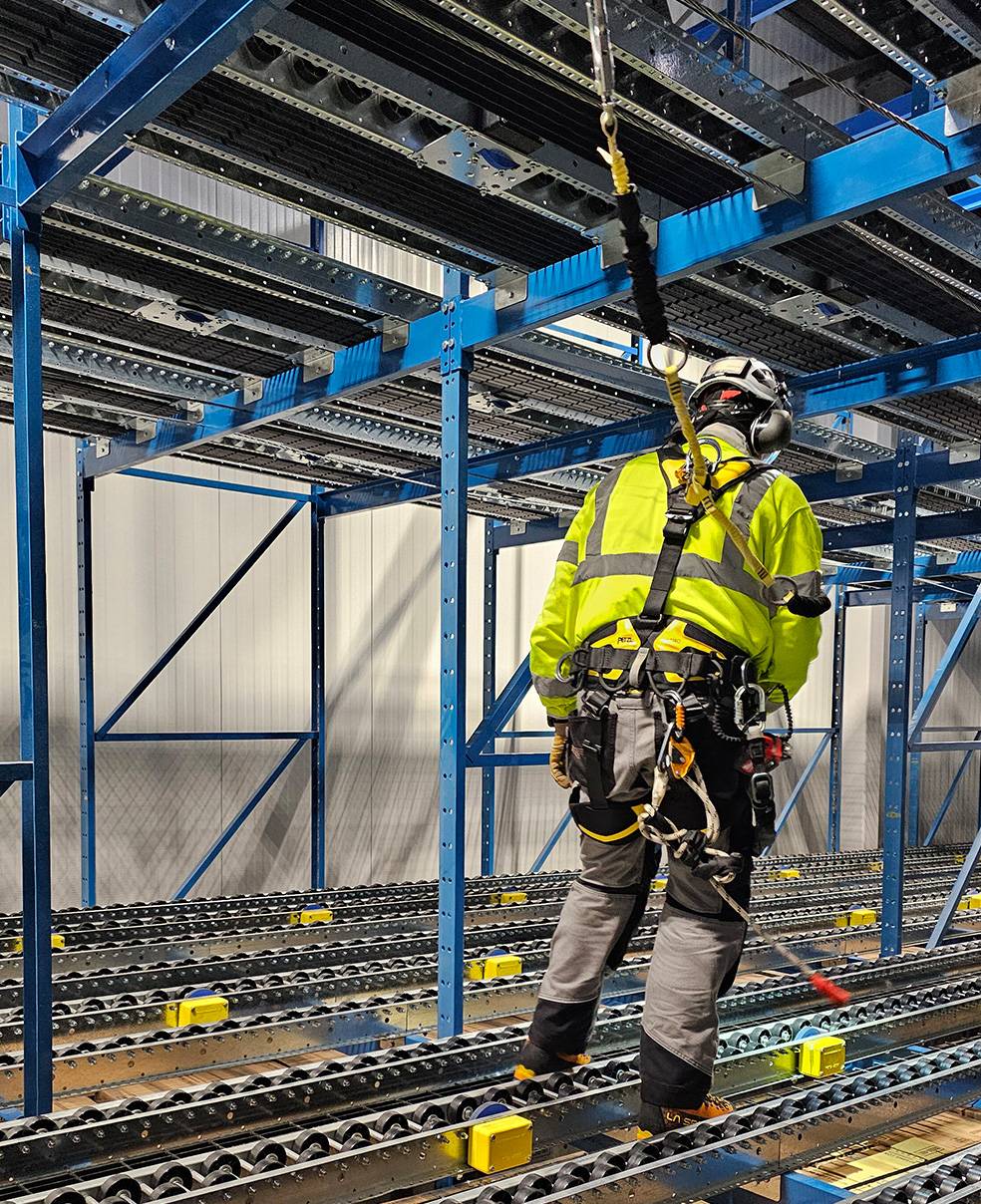

We at RAKSafe® are dedicated to enhancing safety throughout your warehouse operations with innovative solutions. Our focus? To seamlessly integrate world class safety systems into your existing operations. We're not just suppliers; we're partners in your journey towards a safer, more efficient workplace. With our groundbreaking iMPAC Upgrade Solutions and expertly assembled RAKSafe® Entry Systems including PPE Safety Kits, Fall Protection Lanyards, Horizontal Lifelines, and Ladder Safety Systems, we provide solutions that blend effortlessly into your operations. Step into a world where safety is synonymous with efficiency, thanks to RAKSafe®. Let's build a safer future together, with customer engineered safety solutions specific to your needs.

RAKSafe® isn't just a supplier, they're our safety lifeline in the warehouse.

40

Years

Experience

in Safety

Precision in Safety. Confidence in Protection.

The team at RAKSafe® brings 40+ years of collective expertise to the forefront of warehouse and factory floor safety. Our journey spans decades of dedicated service, securing, and assuring the safety of numerous industrial spaces nationwide. We pride ourselves on our collaboration with industry giants like Petzl, Columbus McKinnon, Bole, and others, enabling us to deliver not just products, but comprehensive safety solutions. Every RAKSafe® product is a testament to our unwavering dedication to precision in safety and the confidence it instills.

Our customers know…

“RAKSafe® provides appropriate advice and expertise when delivering solutions that address our warehouse safety concerns and issues.” - LOGISTICS MANAGER

Having the right tools for maintenance and repairs operations ensures our success getting the plant up and running safely and consistently - from shift to shift and in all processes. – COOLER MANAGER – millions of gallons produced each day.

"RAKSafe® provides appropriate advice and expertise when delivering solutions that address our warehouse safety concerns and issues."

- PLANT MANAGER

Our Solutions

Products & Services.

RAKSafe® offers a variety of products and services that keep you safe and enhance your current capabilities. We pride ourselves on working with industry leaders to provide safety products and solutions that exceed ANSI and OSHA requirements. Your business is our business. Let us work with you so we can help you safeguard your workforce, operations, and future.

WARNINGS

General Principles For Work At Height

Carefully read all “Instructions for Use” for any equipment used in this advice before applying the advice given. You must read and understood the information provided in the “Instructions for Use” to be able to understand the information provided here.

Mastering techniques requires training. Work with a professional to confirm your ability to perform these techniques safely and independently before attempting them unsupervised.

Warning

- You must have understood and retained the information from your products' Instructions for Use to be able to apply the techniques presented in this document

- Gaining an adequate apprenticeship in appropriate techniques and methods of protection is your own responsibility. RAKSafe® Solutions are given for information only, with no guarantee of their effectiveness in your specific working situation. The relevance of these solutions varies by context, so always do your own risk analysis in the field

- Mastering the techniques presented here requires specific training and practice; work with a specialized organization for all training activities

General Information - Falls

The risk of falling is a key concept to master when working at height. The severity of a fall depends on independent factors:

- The weight of the user, including his equipment: The greater the weight, the more energy to be dissipated during the fall.

- The length of the fall: The longer the fall, the more energy to be dissipated during the fall. The risk of hitting an obstacle is also greater.

- The position in relation to the anchor: When the worker moves above his anchor, the severity of the potential fall increases. The fall factor concept is sometimes used to describe the position of the worker in relation to the anchor and the severity of the fall. This concept applies to climbing, restraint, or work positioning situations, when a dynamic rope lanyard is used.

Precautions for the type of system used. The Instructions for Use specify the limitations for use of equipment, particularly in terms of length of a fall and the position of the worker in relation to the anchor.

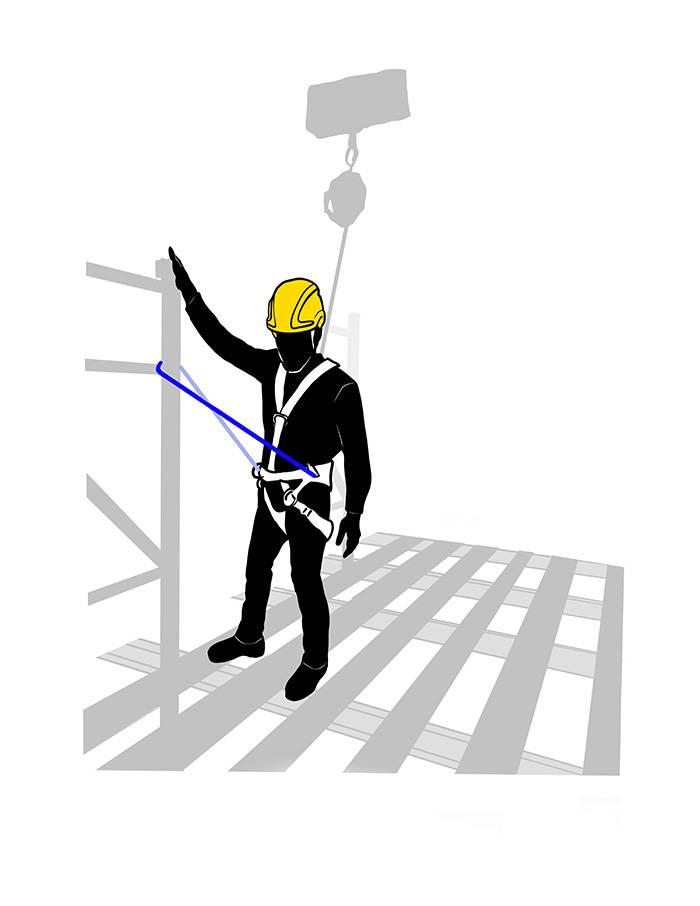

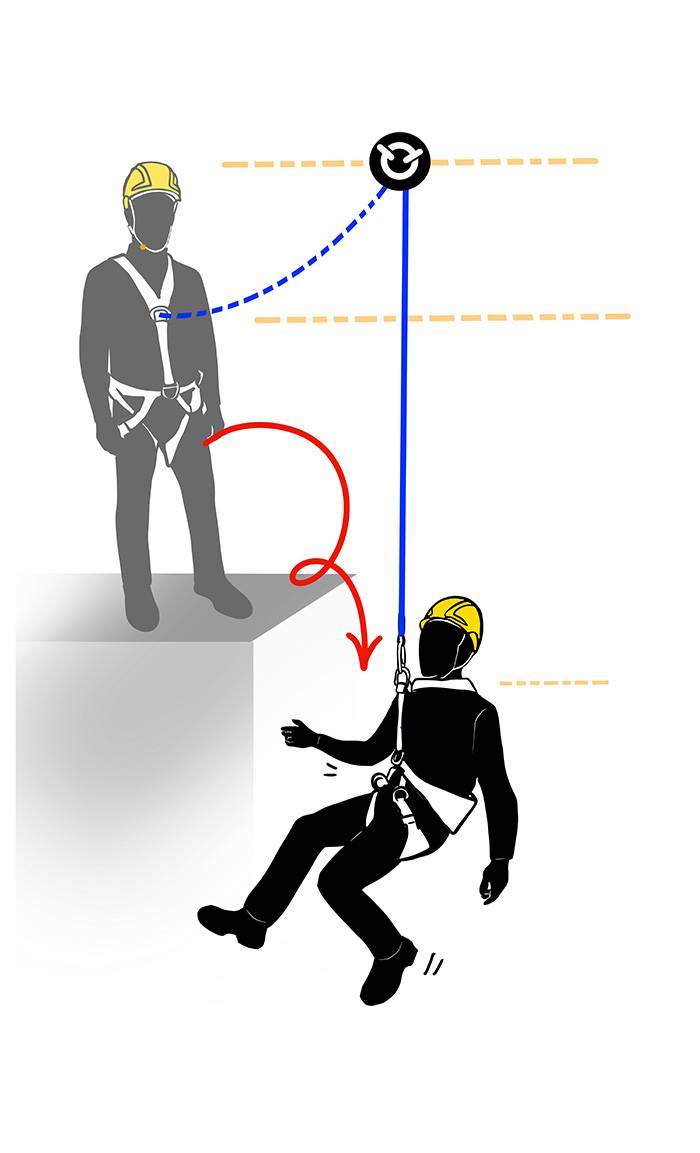

Work Positioning

A work positioning system supports the user and allows him to position himself precisely, supported or suspended. This system is not designed to arrest a fall; the user must be under tension on his positioning system.

The work positioning system must be completed with a fall arrest system.

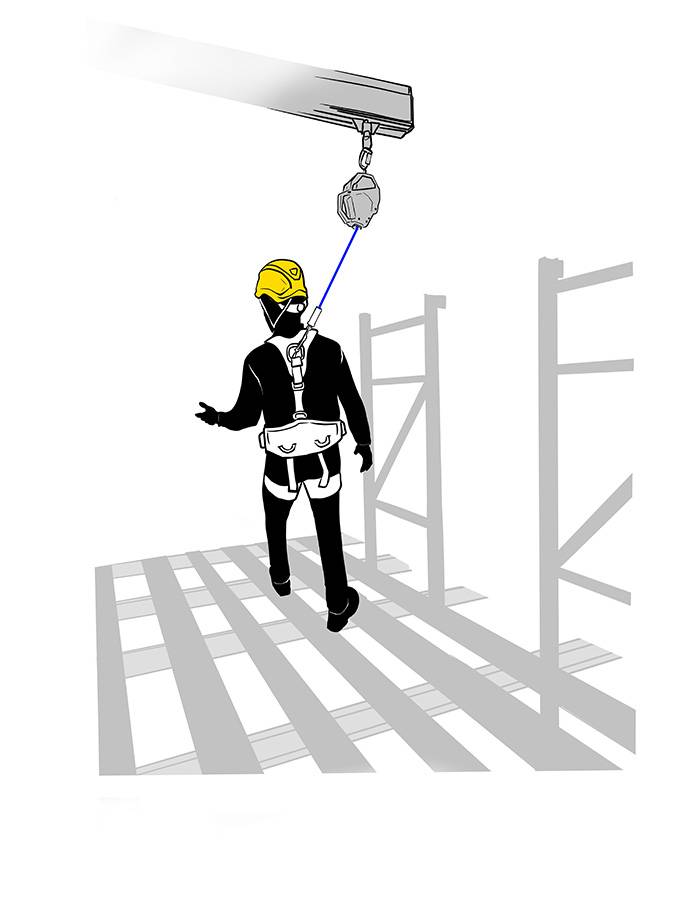

Fall Arrest

The fall arrest system is a belay system that is independent of the progression or work positioning system, connected to the A (fall arrest) attachment point of the harness.

The fall arrest system does not prevent a free fall. Its role is to arrest the fall while limiting the impact force experienced by the user. It must therefore be used with enough clearance to allow for a free fall.

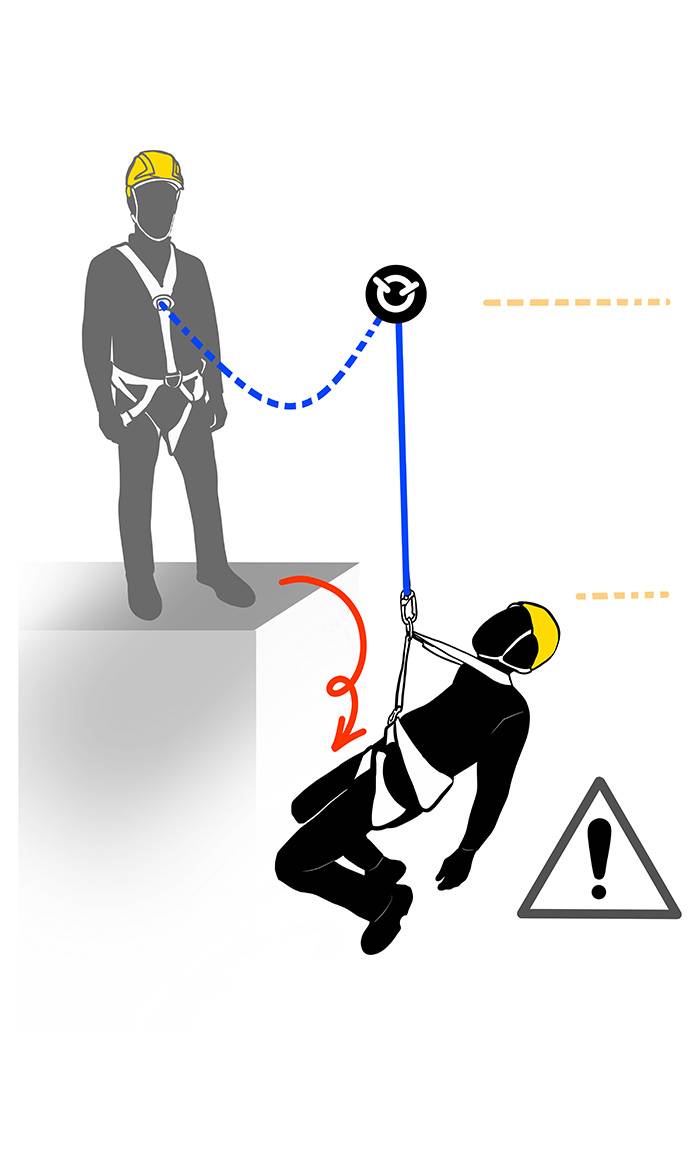

Anticipating rapid evacuation

- Limiting the effects of inert suspension:

In case of a fall where the worker loses consciousness or is incapacitated, inert suspension in the harness presents a mortal danger requiring urgent treatment. Work teams must be equipped and trained to quickly evacuate an injured team member. - Evacuating a victim without assistance:

Procedures for evacuating workers should be determined whenever a new work site is established.

Releasable systems can be created during installation of working ropes to allow evacuation from below.

Working alone must be prohibited: a worker may find himself alone at height, but at least one person trained in evacuations should be present and equipped on site.

Limiting the impact force (absorption of the energy of a fall):

-

A fall arrest system must ensure that the impact force experienced by the user does not exceed 6 Kn (1,348 lbs.).

-

A fall arrest system usually has an energy absorber. It is designed to limit the impact force for a predefined maximum fall length, under the conditions specified in its Instructions for Use.

-

A dynamic rope lanyard has a low capacity for energy absorption. Its use requires great caution: reducing the length of a potential fall and staying in a work position below the anchor.

-

A webbing lanyard or a cable, with no capacity for energy absorption, cannot be used to arrest a fall.

Clearance:

Clearance MUST CONSIDER:

- The stopping distance of the mobile devices or the length of the lanyard (A)

- The tearing length of the energy absorber (B)

- The average height of the user (C)

- A safety margin (D)

- The potential elongation of the support (rope stretch) (E)

A clearance estimate is proposed in the Instructions for Use for each device.

What is clearance?

Clearance is the minimum amount of clear space below the user that prevents the user from hitting an obstacle in case of a fall. This minimum amount of clear space takes into account the length of the system, the tearing of the energy absorber, an average distance between the harness attachment point and the worker's feet (1.5 m) and a safety margin required by the standard (1 m).

.jpg?_t=1734724154)

-320x456.jpg?_t=1734724155)